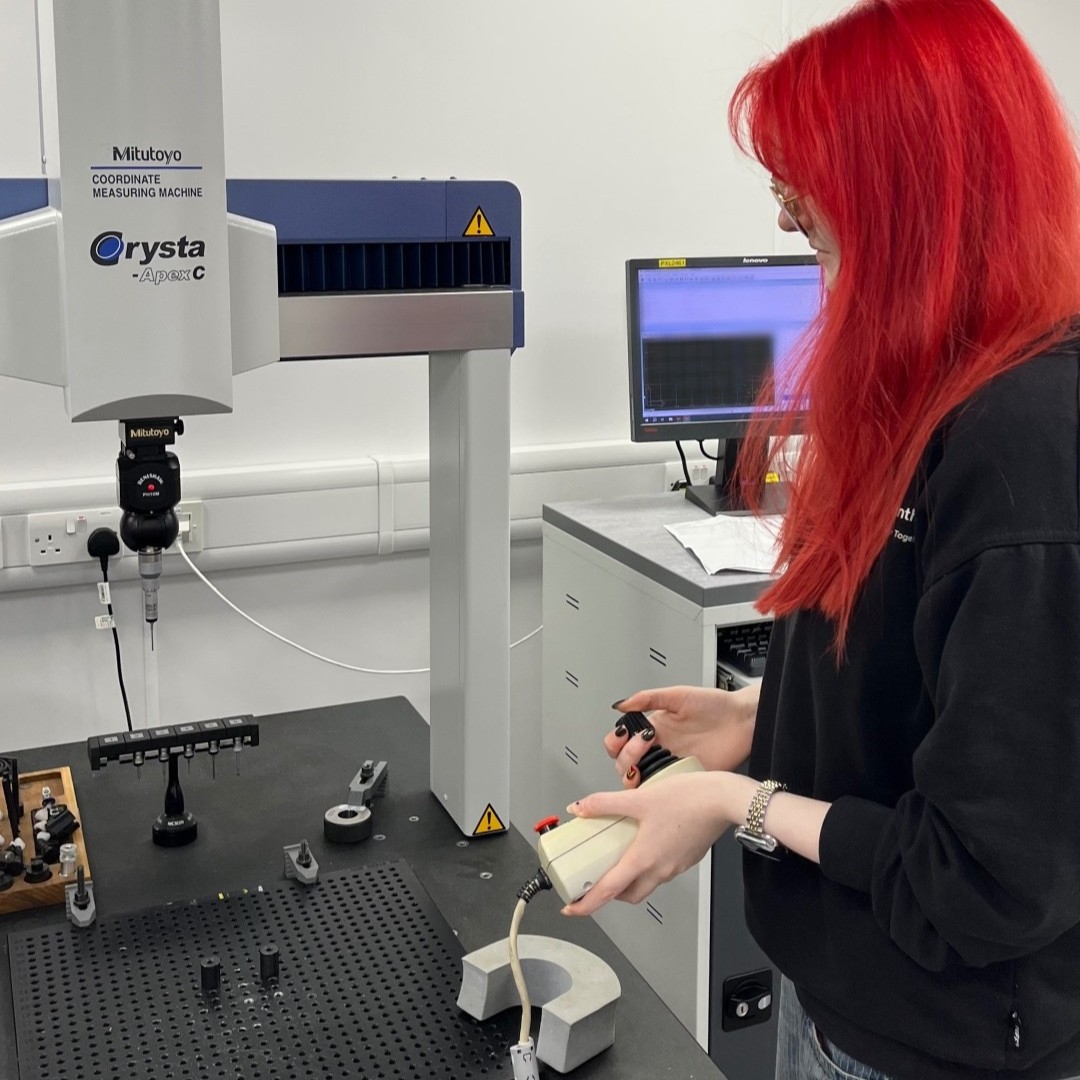

Our calibration team is a small team of three. My colleagues have over 60 years of experience between them and they’re brilliant to work with. They’re really supportive and always happy to explain things. We’re also part of a wider team of about twenty people, and we’re all responsible for making the replacement joints correctly. It’s nice knowing that even though I’m an apprentice, I have real responsibilities and a team I can rely on.

Metrology Technician

Brad Purcell