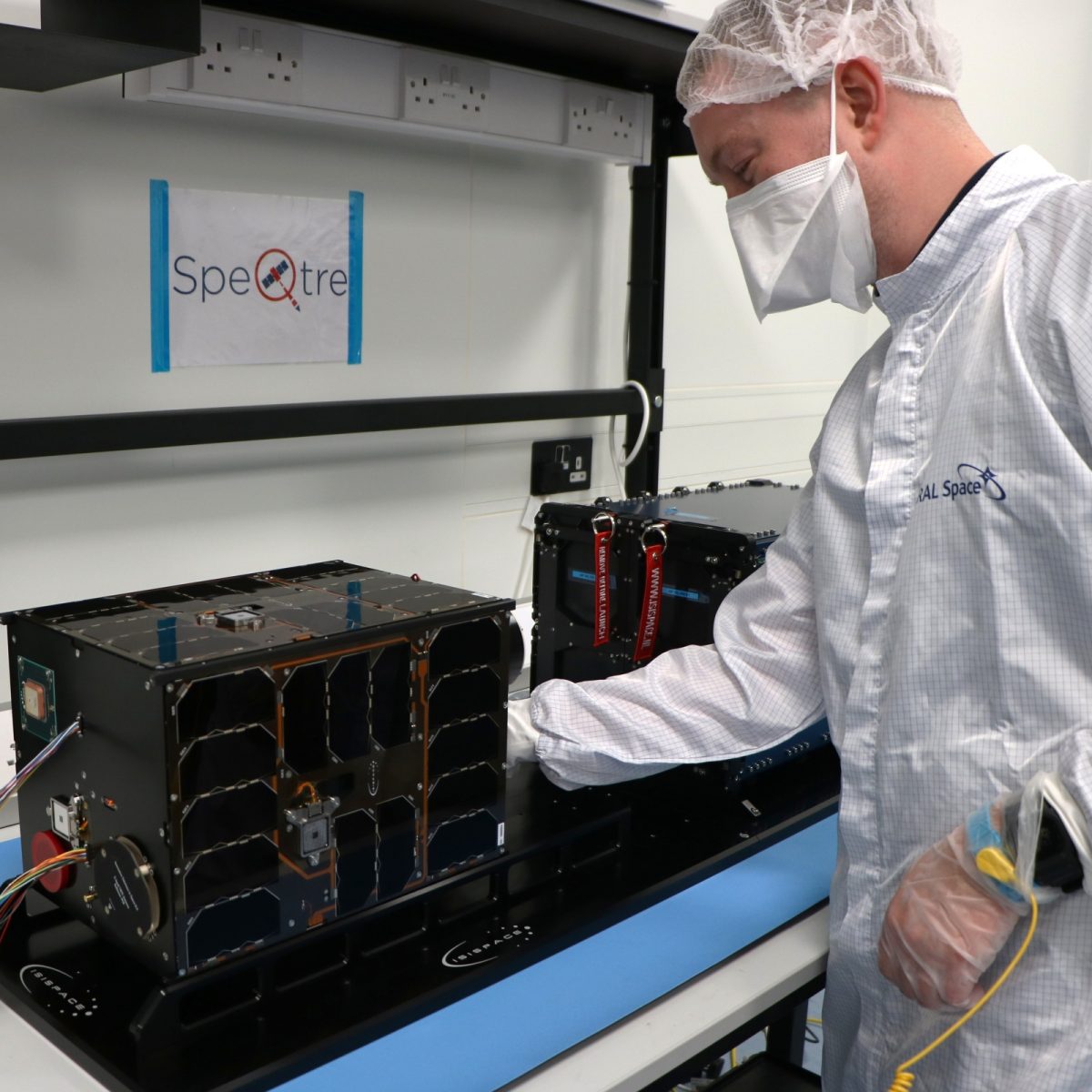

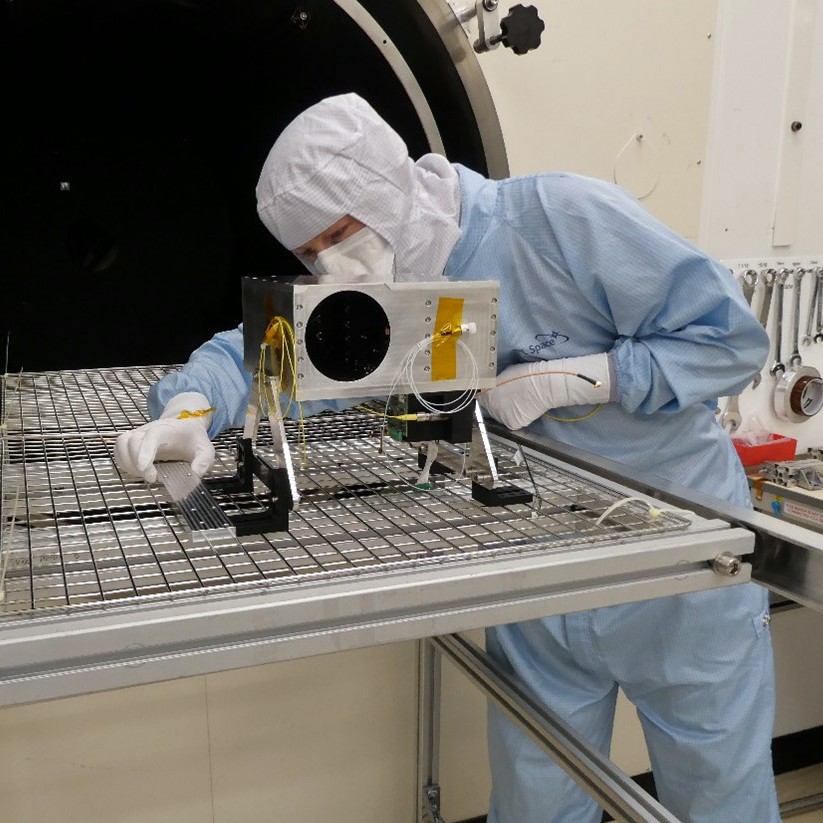

When we’ve got a project deadline, everyone pulls together. We each take on our part, help each other out and get it done. For one project, they’d already paid for the rocket launch before we even started building the satellite – no pressure!

There’s a good mix of people in the team, from technicians like me to others who organise parts and materials. We also work with all sorts of experts. You’d be surprised how many big projects depend on one really skilled person somewhere - sometimes we have to wait for one person from outside the organisation to make a part, because we know they will make the best part for the job.