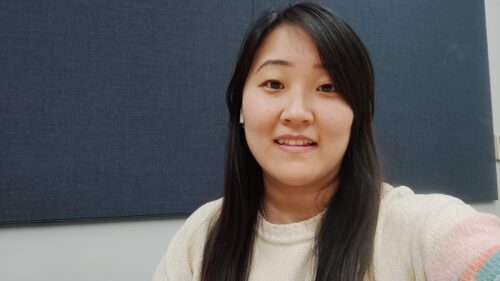

There are seven of us in the CAD department and about fourteen people altogether in the office team. Everyone gets on well and there’s a good mix of ages and experience.

Most of us have worked our way up from the bench in the workshop, so there’s loads of shared knowledge and experience of working as a joiner too. If I ever get stuck on something, I know there’s always someone I can ask who’s seen it before.