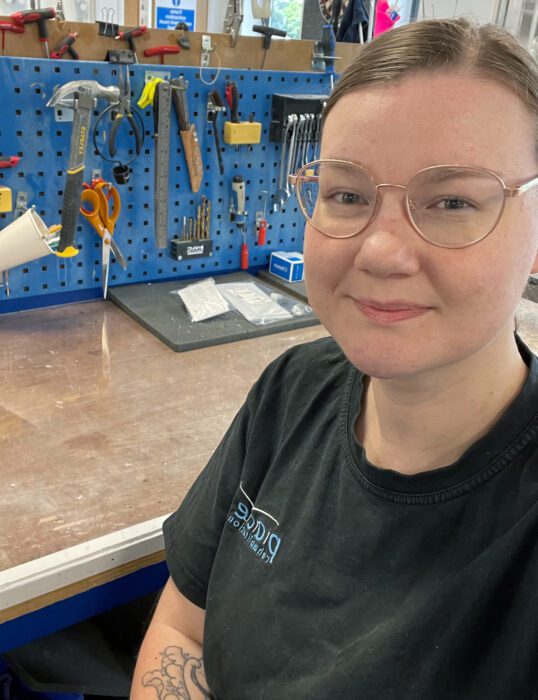

If so, you have one of the skills you need to be a great technician

Do you enjoy solving problems?

Technicians do interesting and important jobs in almost every part of the economy. You might not always see us, but you definitely see the difference we make.

Not sure if you enjoy problem solving?

We’ve picked 100 roles to help you learn about some of the exciting technician jobs out there

And with thousands of other interesting technician roles across almost every kind of industry – there’s a good chance that there’ll be one out there that you’d enjoy.